MACHINE PARTS

SHELVING ACCESSORIES

LOGISTICS ACCESSORIES

providing cost-effective sheet metal stamping products and supporting services for multiple industries such as logistics equipment, new energy, automobiles, electronic appliances, mechanical equipment, and communication equipment.

SHEET METAL PARTS

STAMPED PARTS

will continue to deeply cultivate the stamping and sheet metal field, continuously introduce advanced technology and equipment, optimize production processes, and strive to become a leading sheet metal stamping manufacturing service provider

We will work together with our customers to achieve win-win results and create value.

PRECISION MANUFACTURING,

QUALITY FIRST,

AND CUSTOMER FIRST

including high-precision CNC punching machines, laser cutting machines, bending machines, welding robots, stamping die processing centers,

Product Display

Main categories: Machine parts, Shelving accessories, Logistics accessories

-

Handle Reinforcement Block

304 stainless steel

Strengthen connection stability: Fill the gap between the handle and the installation surface, disperse external impact, avoid handle loosening, deformation or detachment during long-term use, and adapt to various installation scenarios such as wooden doors, metal doors, cabinet doors, etc.2026-01-26 -

Stainless Steel Cover

304 stainless steel2026-01-26 -

stainless steel water tank

304 stainless steel2026-01-26 -

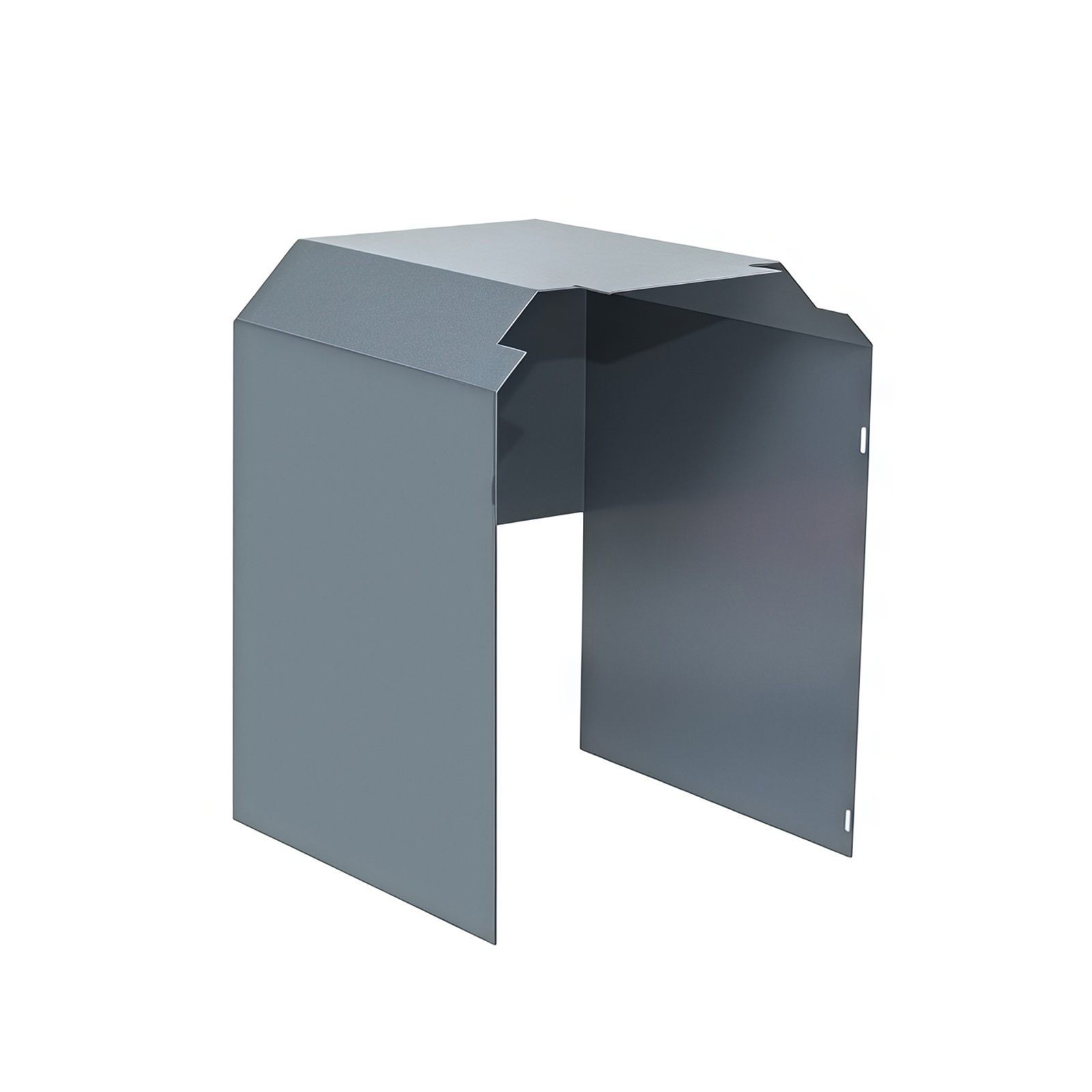

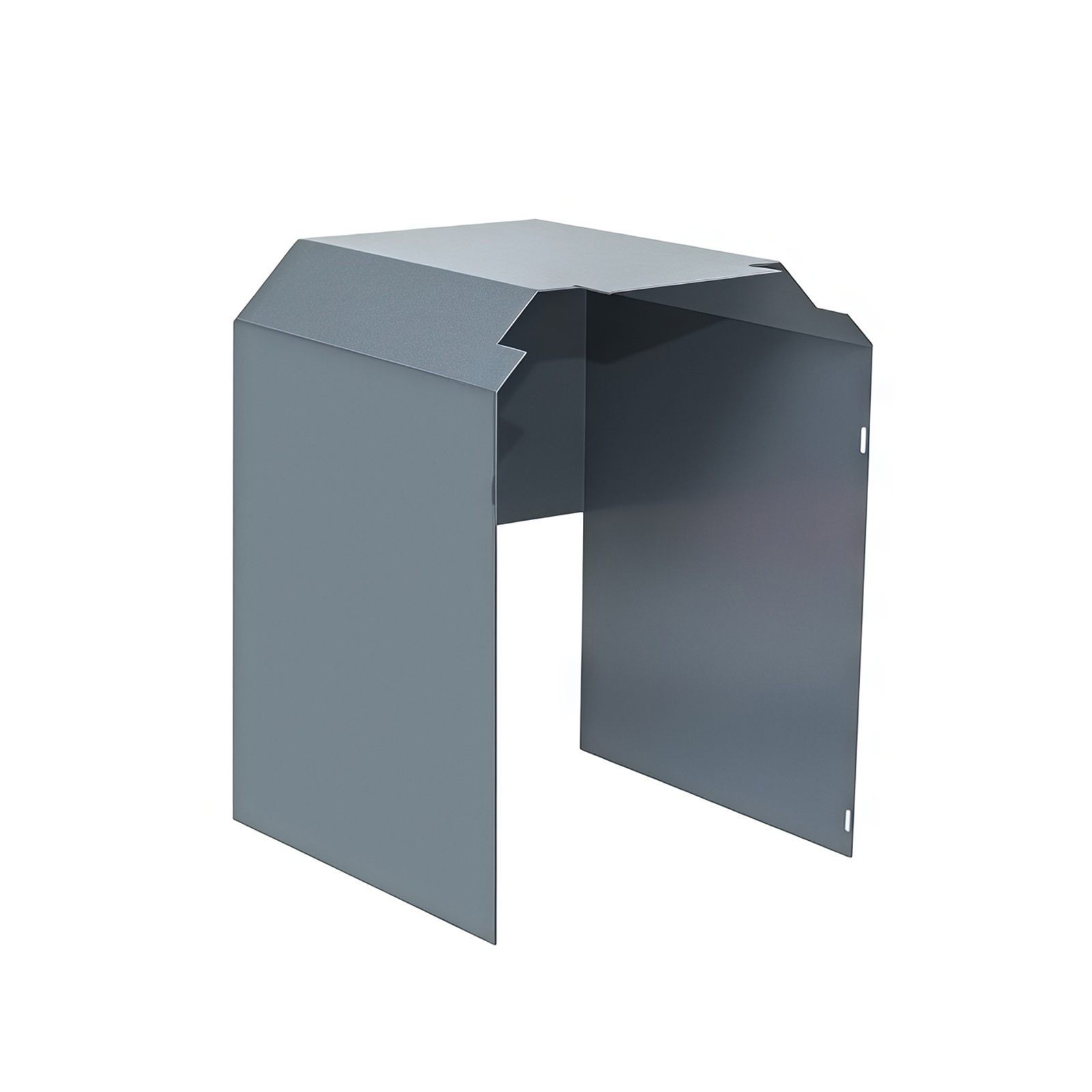

Mechanical protective cover

carbon steel2026-01-26 -

Scenic area lampshade

carbon steel2026-01-26 -

Door lock box

304 stainless steel2026-01-26 -

Door lock box

galvanized sheet2026-01-26 -

lock plate

304 stainless steel2026-01-26

Carbon Steel Stamping Part

By using punch presses and molds, pressure is applied to metal or non-metal sheets, strips, pipes, etc., causing them to undergo plastic deformation or separation, thereby obtaining workpieces with specific shapes, sizes, and properties, which are widely used in various fields such as automobiles, home appliances, electronics, aerospace, etc.

As the core structural component of the product, it plays a role in supporting, connecting, and positioning. For example, car doors, chassis stamping parts, and home appliance shell frames can provide sufficient mechanical strength and rigidity while ensuring lightweight. Used in scenarios that require high-precision assembly, precise machining of molds is used to control the dimensional tolerances of stamped parts within a very small range, meeting seamless fit with other components.

For example, connectors for electronic devices and housing parts for instruments and meters. As the shell or cover of a product, it can protect internal parts from damage caused by external dust, moisture, and impact, and achieve a beautiful decorative effect through surface treatment (such as spraying, electroplating). For example, metal frames for mobile phones and stamped parts for refrigerator door panels.

Handle Reinforcement Block

304 stainless steel

1. Strengthen connection stability: Fill the gap between the handle and the installation surface, disperse external impact, avoid handle loosening, deformation or detachment during long-term use, and adapt to various installation scenarios such as wooden doors, metal doors, cabinet doors, etc.

2. Extend service life: By balancing the load-bearing structure, reduce the wear of the handle base and installation site, and lower the probability of component damage caused by local stress concentration.

3. Compatible with multiple specifications of handles: It is compatible with stainless steel handles of different sizes and styles, easy to install, and does not require additional modification of installation holes.

Get A Free Quote

If you are searching for information about our products, please submit your inquiry by filling out the form below and our customer care team will make a reply. Use a quote template to create your price quote. A price quote, estimate, service quote, or sales quote is an agreement between a customer and a vendor to provide services and products at an agreed-upon price.

PRODUCT CATEGORIES

Sheet metal parts

Stamped parts

Jiangsu Qianyi Automation Technology Co., Ltd

CONTACT US

MAIN CATEGORIES

Machine parts

Shelving accessories

Logistics accessories